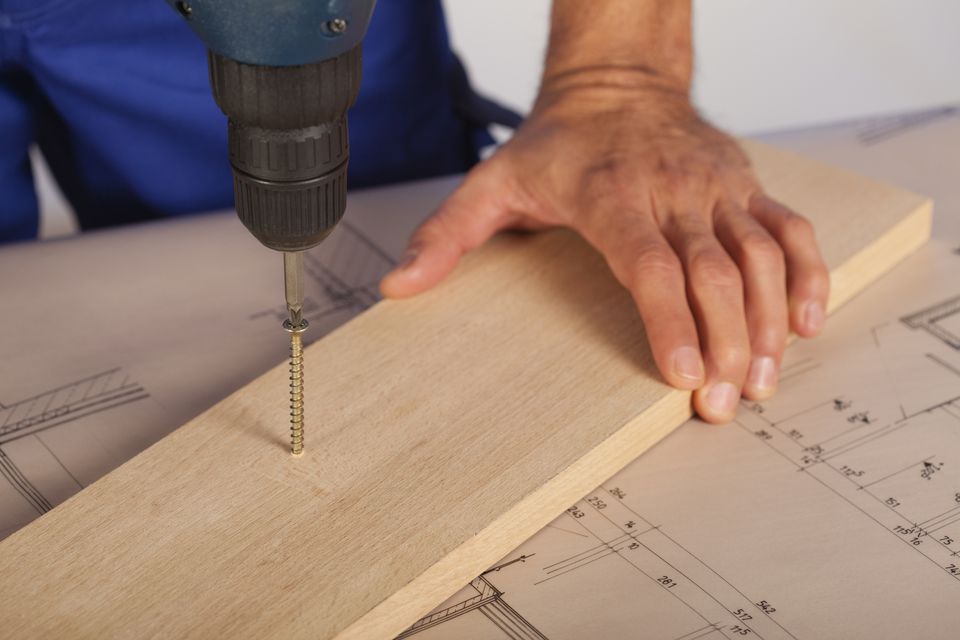

A screw is an alternative to a nail, it is much stronger and has a thread. The screws are tempered, which makes them even stronger than screws and screws. It is very convenient to use them, so many masters of various professions choose screws. You can find out how to select them here https://drilling-it.com/best-screws-for-fence-pickets-reviews/. Of course, the size of the screws matters, small ones are designed for small jobs and are often used:

- in decorative arts (paintings, crafts, etc.);

- in construction (drywall fasteners, wallpaper, small decor details);

- in the manufacture of various goods.

Large screws and medium sizes are most often used for finishing work in buildings and in construction. Screws are not only of different sizes, but also colors, black are more “popular”. A special difference between wood screws is a wide carving and an elongated barrel without thread from the cap.

Types of screws for wood

- Special screws. Perhaps the best of all options for working on wood is the choice of special screws. They cope perfectly with their main task – to fasten without gaps. And this is important when performing such tasks as, for example, fixing the floorboard. Due to incomplete threading, when twisting at an angle of 45 °, the board is fastened without gaps.

- Terrace screws. If special screws are used mainly for interior work, then terrace screws are great for external ones. Wood is not a high-strength material and is subject to seasonal rainfall. Over time, the wood begins to stagger, so that this does not happen, use terrace screws. They have a double thread, which tightly (like tees) clamps wooden parts and maintains stability. Terrace screws are not corroded. Because they are produced from stainless steel.

- Universal screws. Compared to conventional forced screws, universal screws are much better and more often used when working on wood. But universal screws are much inferior to terrace and special. For a greater effect, it is better to use a universal screw paired with a nylon dowel, so the fasteners will be more reliable. Universal screws are similar to press washer screws, which are used not for wood, but for fastening metal sheets. It is worth noting that a universal screw with a press washer is not an ideal solution, because high-quality woodwork cannot be achieved with them. Using them, it is worthwhile to be prepared for the fact that they fasten parts too tightly, chop wood and leave a gap.

Screw Features

“Mill” – this is the name of the screws that have a cutter at the end of the thread, and even so, have incomplete threads throughout the screw. However, due to this, the part is strongly fixed, friction disappears and most importantly, there are no gaps. Such fasteners are considered very good. Cracking wood is an unpleasant moment that can be overcome with the help of special screws. The shape of the tip matters here:

- the tip has special cutting edges;

- the turns of the tip or thread are sawtooth;

- flowing groove (a solid groove looks like a drill. A hole appears in the part, and then the screw easily enters, pushing out the chips. Thanks to this, cracking does not occur);

- different combination of hole shapes.

The part may also crack due to the screw being screwed in too tightly when the cap is literally buried in the material. This most often happens when the master does his job unprofessionally or tries to hide how to drown the screw as deep as possible. When using special screws, this situation does not occur, special countersink ribs under the head will help to avoid cracking.